What's New

2022(January-June)

-

2022.6.16

-

2022.6.15

-

2022.6.14

-

2022.6.7

-

2022.5.27

-

2022.5.2

-

2022.4.22

-

2022.3.28

-

2022.3.21

-

2022.3.16

-

2022.2.11

-

2022.2.1

-

2022.1.27

-

2022.6.16

A paper on the mechanism of the quenching effect of laser PBF method on the formation of equiaxed grains in Al alloys has been published as an OA paper in the Journal of Alloys and Compounds (JALCOM, IF=5.316). This is a joint research with Koizumi Lab.

Masayuki Okugawa, Yuta Ohigashi, Yuya Furishiro, Yuichiro Koizumi*, Takayoshi Nakano:

Equiaxed grain formation by intrinsic heterogeneous nucleation via rapid heating and cooling in additive manufacturing of aluminum-silicon hypoeutectic alloy,

Journal of Alloys and Compounds,

919, (2022), 165812: 1-6.

https://doi.org/10.1016/j.jallcom.2022.165812Click here for this paper.

Abstract

The high strength of Al-Si hypoeutectic alloys additively manufactured by powder-bed fusion is of great scientific interest. To date, the mechanism of grain refinement near the fusion line, which contradicts conventional Hunt’s columnar–equiaxed transition criteria, remains to be elucidated. Here we present the first report on the mechanism of grain refinement. When a laser was irradiated on cast Al-Si alloy consisting of coarse α-Al grain and α-Al/Si eutectic regions, grain refinement occurred only near the eutectic regions. This strongly suggests that the Si phase is crucial for grain refinement. Multi-phase-field simulation revealed that rapid heating due to the laser irradiation results in unmelted Si particles even above the liquidus temperature and that the particles act as heterogeneous nucleation sites during the subsequent re-solidification. These results suggest the feasibility of a novel inoculant-free grain refinement that is applicable to eutectic alloys comprising phases with a significant melting point difference. -

2022.6.15

A paper on the recrystallization behavior of IN738LC fabricated by metal additive manufacturing has been published in Crystals as an OA paper.

Shinya Hibino*, Kazushige Fujimitsu, Makoto Azuma, Takuya Ishimoto, Takayoshi Nakano*:

Effects of Recrystallization on Tensile Anisotropic Properties for IN738LC Fabricated by Laser Powder Bed Fusion,

Crystals, 12(6), (2022), 842: 1-14.

https://doi.org/10.3390/cryst12060842Click here for this paper.

Abstract

This study demonstrates the effects of recrystallization on tensile properties and the anisotropy of IN738LC, a typical γ’ precipitation-strengthened alloy, at both room and high temperatures via the laser powder bed fusion process. The nonrecrystallized columnar microstructure, subjected to standard IN738LC heat treatment up to 1120 °C, and the almost fully recrystallized microstructure, heat-treated at 1204 °C, were compared. The tensile properties strongly depend on whether recrystallization was completed as well as the tensile direction. This can be explained by microstructure characterization, featuring the Taylor factor in the tensile direction, average grain size estimated by ellipse approximation, and the relationship between the grain shape and tensile direction. The shape of the recrystallized grains and the distribution of coarse MC carbides inside the recrystallized grains were determined by the microstructure in an as-built state. In high-temperature tensile tests conducted in the horizontal direction, the separation of the columnar grains caused a brittle fracture. In contrast, dimples were observed at the fracture surface after recrystallization, indicating scope for further improvement in ductility.

Keywords: laser powder bed fusion; IN738LC; heat treatment; recrystallization; MC carbide; anisotropy; tensile property -

2022.6.14

A paper demonstrating the effectiveness of the "honeycomb tree structure," the basic principle of the UNIOS PL spacer marketed by Teijin Nakashima Medical Limited, has been accepted for publication in "The Spine Journal" of the North American Spine Societ

Takuya Ishimoto, Yoshiya Kobayashi, Masahiko Takahata, Manabu Ito, Aira Matsugaki, Hiroyuki Takahashi, Ryota Watanabe, Takayuki Inoue, Tadaaki Matsuzaka, Ryosuke Ozasa, Takao Hanawa, Katsuhiko Yokota, Yoshio Nakashima, Takayoshi Nakano*:

Outstanding in vivo mechanical integrity of additively manufactured spinal cages with a novel "honeycomb tree structure" design via guiding bone matrix orientation,

The Spine Journal, (2022),

https://doi.org/10.1016/j.spinee.2022.05.006 -

2022.6.7

Our paper on successful single-crystal fabrication using flat-top laser-based nickel powder 3D lithography has been accepted for publication in Additive Manufacturing Letters and published as an OA article.

Dennis Edgard Jodi, Tomonori Kitashima*, Yuichiro Koizumi, Takayoshi Nakano, Makoto Watanabe:

Manufacturing single crystals of pure nickel via selective laser melting with a flat-top laser beam,

Additive Manufacturing Letters, 3, (2022), 100066: 1-7.

https://doi.org/10.1016/j.addlet.2022.100066 -

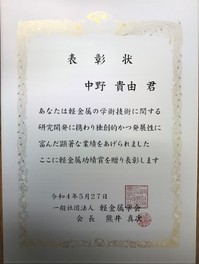

2022.5.27

Dr. Nakano received the Light Metal Achievement Award from the Japan Institute of Light Metals.

Takayoshi Nakano: Achievement Award for Light Metals, Japan Institute of Light Metals

Certificate of Commendation from Chairman Kumai

Commemorative gift from President Imasu

-

2022.5.2

A paper on bone orientation around anchor screws has been published as an open access article in the Journal of Hard Tissue Biology.

Takaaki Matsumoto, Satoru Matsunaga, Masaaki Kasahara, Norio Kasahara, Takayoshi Nakano, Takuya Ishimoto, Yasushi Nishii:

Evaluation of the Microstructural Characteristics of Bone Surrounding Anchor Screws Placed under a Horizontal Load by Exploring the Orientation of Biological Apatite Crystals and Collagen Fiber Anisotropy,

Journal of Hard Tissue Biology 31[2], (2022), 79-86.Click here for this paper

Abstract

The objective of this study was to carry out quantitative evaluations of the microstructural characteristics of bone surrounding anchor screws placed under a horizontal load and the microstructural characteristics of bone on the compressed and non-compressed sides of anchor screws by investigating the orientation of biological apatite (BAp) crystals and collagen fiber anisotropy. Anchor screws were implanted in the femurs of adult rats. They were divided into those placed under a horizontal load (horizontal loading group, n = 4), those not placed under a horizontal load (unloaded group, n = 4), and a sham group of rats that did not undergo femoral anchor screw implantation. In addition to histological observations, Bap crystal orientation and collagen fiber anisotropy were also analyzed. Osteocytes adjacent to anchor screws on the compressed side in the horizontal loading group were rounder in shape than those in normal femurs, the unloaded group, and on the non-compressed side in the horizontal loading group. Collagen fibers showed anisotropy on the non-compressed side in the horizontal loading group. BAp crystals also showed a uniaxial preferential orientation in the direction of traction on the compressed side in the horizontal loading group. These results demonstrated that the osteogenesis of bone around anchor screws placed under a sustained horizontal load gave this bone structural characteristics that differed in some respects from those of normal bone. They also showed that this bone acquired micro/nanostructural characteristics adapted to its new mechanical environment.Key words: Anchor screw, Bone quality, Biological apatite crystal, Second harmonic generation images

-

2022.4.22

An invited commentary paper on microstructure control by metal additive manufacturing was published in JOM as open access.

Koji Hagihara, Takayoshi Nakano*:

Control of Anisotropic Crystallographic Texture in Powder Bed Fusion Additive Manufacturing of Metals and Ceramics—A Review,

Journal of Metals (JOM), 74, (2022), 1760–1773.

DOI: https://doi.org/10.1007/s11837-021-04966-7Click here for this paper.

Abstract

Additive manufacturing (AM) enables the production of complex, net-shape geometries. Additionally, in AM of metal and ceramics, which has received less attention, the microstructure and texture of the product can be arbitrarily controlled by selecting appropriate process parameters, thereby enabling unprecedented superior properties. This paper discusses recent progress pertaining to texture evolution mechanisms and control methods, with an emphasis on selective laser melting. One of the unique characteristics of AM is that the texture can be varied as a function of position within the product by controlling the scan strategy. The transient behavior of the texture and the factor used to control it via the scan strategy are discussed. In addition, the texture evolution behavior of face- and body-centered cubic as well as noncubic materials is discussed. The importance of the crystallographic “multiplicity” of the preferential crystal growth direction is described to understand the evolution behavior of the texture in such materials. -

2022.3.28

A paper on low modulus Ti-Nb-Fe-Zr alloys was published as an OA paper in Trans. Nonferrous Met. Soc. China (IF=2.917)

Qiang Li, Qi Huang, Jun-jie Li, Qian-feng He, Masaaki Nakai, Ke Zhang, Mitsuo Ninomi, Kenta Yamanaka, Akihiko Chiba, Takayoshi Nakano:

Microstructure and mechanical properties of Ti-Nb-Fe-Zr alloys with high strength and low elastic modulus,

Transactions of Nonferrous Metals Society of China, 32, (2022), 503-512.

DOI:https://doi.org/10.1016/S1003-6326(22)65811-4Click here for this paper.

Abstract

Zr was added to Ti–Nb–Fe alloys to develop low elastic modulus and high strength β-Ti alloys for biomedical applications. Ingots of Ti–12Nb–2Fe–(2, 4, 6, 8, 10)Zr (at.%) were prepared by arc melting and then subjected to homogenization, cold rolling, and solution treatments. The phases and microstructures of the alloys were analyzed by optical microscopy, X-ray diffraction, and transmission electron microscopy. The mechanical properties were measured by tensile tests. The results indicate that Zr and Fe cause a remarkable solid-solution strengthening effect on the alloys; thus, all the alloys show yield and ultimate tensile strengths higher than 510 MPa and 730 MPa, respectively. Zr plays a weak role in the deformation mechanism. Further, twinning occurs in all the deformed alloys and is beneficial to both strength and plasticity. Ti–12Nb–2Fe–(8, 10)Zr alloys with metastable β phases show low elastic modulus, high tensile strength, and good plasticity and are suitable candidate materials for biomedical implants. -

2022.3.21

MDPI's Materials (IF-3.623) has published an OA paper on the difficulty of lattice modulation observed in the Zr-Nb system.

Mitsuharu Todai, Keisuke Fukunaga, Takayoshi Nakano*:

Athermal ω phase and lattice modulation in binary Zr-Nb biomedical alloys,

Materials, 15, (2022), 2318; 1-13.

DOI:https://doi.org/10.3390/ma15062318Click here for this paper.

Abstract

To further explore the potential of Zr-based alloys as a biomaterial that will not interfere with magnetic resonance imaging (MRI), the microstructural characteristics of Zr-xat.% Nb alloys (10 ≤ x ≤ 18), particularly the athermal ω phase and lattice modulation, were investigated by conducting electrical resistivity and magnetic susceptibility measurements and transmission electron microscopy observations. The 10 Nb alloy and 12 Nb alloys had a positive temperature coefficient of electrical resistivity. The athermal ω phase existed in 10 Nb and 12 Nb alloys at room temperature. Alternatively, the 14 Nb and 18 Nb alloys had an anomalous negative temperature coefficient of the resistivity. The selected area diffraction pattern of the 14 Nb alloy revealed the co-occurrence of ω phase diffraction and diffuse satellites. These diffuse satellites were represented by gβ + q when the zone axis was [001] or [113], but not [110]. These results imply that these diffuse satellites appeared because the transverse waves consistent with the propagation and displacement vectors were q = <ζ 0>* for the ζ~1/2 and <110> directions. It is possible that the resistivity anomaly was caused by the formation of the athermal ω phase and transverse wave. Moreover, control of the athermal ω-phase transformation and occurrence of lattice modulation led to reduced magnetic susceptibility, superior deformation properties, and a low Young’s modulus in the Zr-Nb alloys. Thus, Zr-Nb alloys are promising MRI-compatible metallic biomaterials.Keywords

magnetic resonance imaging (MRI); transmission electron microscopy (TEM); phase transition; electrical resistivity; metallic biomaterials -

2022.3.16

Journal of Materials Engineering and Performance (IF=1.865) published a study on the design and properties of a new beta Ti-Nb-Cr alloy.

Qiang Li, Fei Li, Junjie Li, Zhi Gao, Ke Zhang, Mitsuo Niinomi, Takayoshi Nakano:

Microstructure, mechanical properties, and cytotoxicity of β-Type Ti-Nb-Cr alloys designed by electron parameter,

Journal of Materials Engineering and performance (JMEPEG), (2022), on line.

DOI:https://doi.org/10.1007/s11665-022-06586-xClick here for this paper.

Abstract

A series of b-type Ti-(24-2x)Nb-xCr (at%) (x=0, 1, 2, 3, 4, 5) alloys were designed by using Cr to replace Nb with a fixing average valence electron number (valence electron/atom ratio, e/a ratio) of 4.24. The alloys were prepared by arc melting and then subjected to homogenization, cold rolling and solution treatment. The phases and microstructures were analyzed by x-ray diffraction and optical microscopy. The mechanical properties were measured by tensile tests. The cytotoxicity was evaluated by detecting the proliferation of MC3T3-E1 cells after several days’ culture. With the increase of Cr content, the b stability of the studied Ti-Nb-Cr alloys is gradually increased. Stress-induced martensite transformation is found in Ti-24Nb and Ti122Nb-1Cr and suppressed by more Cr addition. Nonlinear deformation and twinning appear in all the alloys indicating that the b phases are all metastable. The 0.2 proof stress increases with increase of Cr owing the enhanced b stability and solid solution strengthening effect due to Cr addition. Obvious dynamic reinforcement during deformation is found in Ti-22Nb-1Cr leading to higher tensile strength than those of Ti-24Nb and Ti-20Nb-2Cr. The tensile strength continuous increases with Cr content increasing from 2 to 5 . Cytotoxicity is not found in Ti-24Nb and Ti-16Nb-4Cr by observing the growth of mice pre-osteoblast line MC3T3-E1. Ti-16Nb-4Cr shows good comprehensive mechanical properties and non-cytotoxicity, and is a potential candidate for biomaterials. -

2022.2.11

Our research on surface treatment of 316 stainless steel by nitriding has been published as an OA paper in "Metals (IF=2.351)".

Ozkan Gokcekaya*, Celaletdin Ergun*, Turgut Gulmez, Takayoshi Nakano and Safak Yilmaz,

Structural characterization of ion nitrided 316L austenitic stainless steel: Influence of treatment temperature and time

Metals, 12(2), (2022), 306; 1-11.

DOI : https://doi.org/10.3390/met12020306Click here for this paper.

Abstract

The ion nitriding behavior of AISI 316L austenite stainless steel was investigated at different nitriding times (2 h, 4 h, and 9 h) and temperatures (450 °C, 500 °C, and 550 °C). The structural characterization has been assessed by several considerations which can be listed: (i) the evaluation of phase distribution through Rietveld analysis of X-ray diffraction patterns and accompanying peak fitting process, (ii) hardness profile and related nitride layer thickness by microhardness and microscopic measurements, and (iii) displacement measurements to assess the residual stress accumulation. The diffusion of nitrogen atomic species into the sample surface caused a transformation of the γ phase matrix into an expanded austenite (γN) phase, which is recognized with its high hardness and wear resistance. Furthermore, depending on the nitriding condition, chromium nitride (Cr1-2N) and iron nitride (ε-Fe2-3N and γ′-Fe4N) phases were detected, which can be detrimental to the corrosion resistance of the 316L austenite stainless steel. The γN phase was observed in all nitriding conditions, resulting in a significant increase in the surface hardness. However, decomposition of the γN phase with an increase in nitriding temperature eventually altered the surface hardness distribution in the nitriding layer. Considering the phase-type and distribution with the consequent hardness characteristics in the nitride layer, to our best knowledge, this is the first report in which an ion-nitriding temperature of 500 °C (higher than 450 °C) and time of 9 h can be proposed as ideal processing parameters leading to optimal phase composition and hardness distribution for 316L austenite stainless steels particularly for the applications requiring a combination of both wear and corrosion resistance.

Keywords: 316L stainless steel; ion nitriding; phase composition; nitride layer; surface hardness -

2022.2.1

Our research on the suppression of dentin cracking by Zn addition, conducted in collaboration with Prof. Mikako Hayashi, Graduate School of Dentistry, Tohoku University, has been published as an OA paper in Materials & Design (IF=7.991).

Katsuaki Naito, Yasutaka Kuwahara, Hiroko Yamamoto, Yasuhiro Matsuda, Katsushi Okuyama, Takuya Ishimoto, Takayoshi Nakano, Hiromi Yamashita, Mikako Hayashi*:

Improvement of acid resistance of Zn-doped dentin by newly generated chemical bonds,

Materials & Design, 215, (2022), 110412; 1-11.

https://doi.org/10.1016/j.matdes.2022.110412Click here for this paper

AbstractDental caries, the world’s most prevalent infectious disease, is caused by the diffusion of hydroxyl ions into tooth structures. To prevent dental caries, the application of fluoride (F) and zinc (Zn) ions to teeth surfaces are potential effective measures. In this study, The ionic influence, especially the chemical bond of F and Zn, on the acid resistance of dentin were investigated by particle induced X-ray / gamma-ray emission, X-ray diffraction, X-ray photoelectron spectroscopy and X-ray absorption spectroscopy. The results showed Zn was distributed in the limited surface layer of dentin without altering its crystal structure. From the Zn K edge extended X-ray absorption fine structure, Zn incorporated into dentin was surrounded by oxygen and demonstrated four-fold coordination. The bond length and chemical state of Zn–O in Zn doped dentin suggested newly generated Zn–O covalent bond, which may improve acid resistance of dentin. This study showed that the atomic and molecular structures, such as the molecular distances and chemical state, influenced acid resistance of teeth, emphasizing the validity of chemical state analysis for understanding properties in biomaterials.

-

2022.1.27

Our joint research with Professor Yamamoto of Kansai Women's Junior College on the effects of bmp-2 gene transfer on bone formation and bone quality was published as an OA paper in Materials.

Mariko Yamamoto Kawai, Ryosuke Ozasa, Takuya Ishimoto, Takayoshi Nakano, Hiromitsu Yamamoto, Hiroki Maruyama, Kazuhisa Bessho, Kiyoshi Ohura:

Periodontal tissue as a biomaterial for hard-tissue regeneration following Bmps gene transfer,

Materials, 15, (2022), 993;1-10.

https://doi.org/10.3390/ma15030993Click here for this paper.

Abstract

The application of periodontal tissue in regenerative medicine has gained increasing interest since it has a high potential to induce hard-tissue regeneration, and is easy to handle and graft to other areas of the oral cavity or tissues. Additionally, bone morphogenetic protein-2 (BMP-2) has a high potential to induce the differentiation of mesenchymal stem cells into osteogenic cells. We previously developed a system for a gene transfer to the periodontal tissues in animal models. In this study, we aimed to reveal the potential and efficiency of periodontal tissue as a biomaterial for hard-tissue regeneration following a bmp-2 gene transfer. A non-viral expression vector carrying bmp-2 was injected into the palate of the periodontal tissues of Wistar rats, followed by electroporation. The periodontal tissues were analyzed through bone morphometric analyses, including mineral apposition rate (MAR) determination and collagen micro-arrangement, which is a bone quality parameter, before and after a gene transfer. The MAR was significantly higher 3–6 d after the gene transfer than that before the gene transfer. Collagen orientation was normally maintained even after the bmp-2 gene transfer, suggesting that the bmp-2 gene transfer has no adverse effects on bone quality. Our results suggest that periodontal tissue electroporated with bmp-2 could be a novel biomaterial candidate for hard-tissue regeneration therapy.

Keywords: periodontal tissue; BMP; gene therapy; collagen micro-arrangement; bone quality