最新情報

2025年(7月~12月)

-

2025.12.28

-

2025.12.19

-

2025.12.17

-

2025.12.14

-

2025.12.13

-

2025.12.4

-

2025.12.4

-

2025.11.27

-

2025.11.25

-

2025.11.19

-

2025.11.14

-

2025.11.12

-

2025.11.12

-

2025.11.12

-

2025.11.11

-

2025.11.10

-

2025.11.10

-

2025.11.10

-

2025.11.8

-

2025.11.7

-

2025.11.6

-

2025.11.2

-

2025.11.1

-

2025.11.1

-

2025.10.29

-

2025.10.28

-

2025.10.16

-

2025.10.9

-

2025.10.9

-

2025.9.29

-

2025.9.26

-

2025.9.24

-

2025.9.23

-

2025.9.17

-

2025.9.17

-

2025.9.12

-

2025.9.11

-

2025.9.9

-

2025.9.6

-

2025.9.5

-

2025.9.5

-

2025.9.3

-

2025.9.3

-

2025.9.3

-

2025.9.2

-

2025.9.1

-

2025.8.22

-

2025.8.22

-

2025.8.6

-

2025.8.1

-

2025.8.1

-

2025.8.1

-

2025.7.29

-

2025.7.28

-

2025.7.18

-

2025.7.11

-

2025.7.2

-

2025.7.1

-

2025.12.28

【論文】Materials TransactionsにAl-Si合金の超昇温・超急冷に関する論文が受理されました。

Masayuki Okugawa*, Yuya Furushiro, Seori Motoyama, Yuheng Liu, Takayoshi Nakano, Yuichiro Koizumi: Manuscript number Integrated computational and experimental study on rapid heating and cooling in powder-bed fusion of Al-Si hypoeutectic alloys, Materials Transactions, (2026), in press.

-

2025.12.19

【行事】2025年度忘年会を開催しました。

-

2025.12.17

【論文】Journal of Materials Research and Technologyに金属AM(PBF-LB/M)で造形されたステンレス鋼の陽電子消滅による格子欠陥の同定に関する論文がOA論文として掲載されました。

Masataka Mizuno*, Masaki Otsuka, Kazuhisa Sato, Takuya Ishimoto, Takayoshi Nakano, Hideki Araki: Identification of lattice defects in laser powder bed fusion-fabricated 316L stainless steel by positron annihilation spectroscopy, Journal of Materials Research and Technology, in press, 40, (2026), 188-193.

DOI: https://doi.org/10.1016/j.jmrt.2025.12.147

論文はこちら

PDFはこちら

Abstract

The laser powder bed fusion (LPBF) process often introduces lattice defects, such as vacancies and dislocations, within the fabricated materials because of large thermal gradients and rapid cooling rates. In this study, lattice defects in LPBF-fabricated 316L stainless steel (SS) were quantitatively evaluated using positron annihilation spectroscopy, a sensitive technique for detecting and characterizing vacancies and dislocations. The number of lattice defects increased with the LPBF scan speed. Vacancy concentrations and dislocation densities were determined using component analysis of the positron lifetime spectra. The measured vacancy concentration was comparable to the thermal equilibrium concentration of vacancies at the melting point. Additionally, both vacancy concentration and dislocation density increased with scan speed. The increase in dislocation density in the fabricated 316L SS with increasing scan speed of the LPBF process was confirmed using transmission electron microscopy. This study enables the detection and identification of defects in 316L SS under various temperature conditions, offering insights into the performance of 316L SS across a wider range of operating temperatures. -

2025.12.14

【論文】Journal of Materials Research and Technologyに金属AM(PBF-LB/M)で造形されたステンレス鋼の陽電子消滅による格子欠陥の同定に関する論文がOA論文として受理されました。

Masataka Mizuno*, Masaki Otsuka, Kazuhisa Sato, Takuya Ishimoto, Takayoshi Nakano, Hideki Araki: Identification of lattice defects in laser powder bed fusion-fabricated 316L stainless steel by positron annihilation spectroscopy, Journal of Materials Research and Technology, in press, (2025).

-

2025.12.13

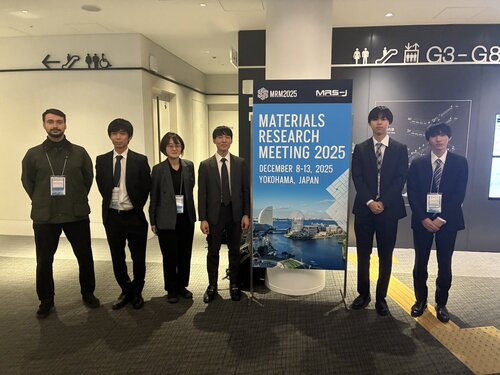

【国際会議】Materials Research Meeting 2025(@パシフィコ横浜,12月8日〜13日)に参加しました。

【Session】

Solidification Microstructure in Ti-V Alloy and Ti1(NbMoTa)2W0.5 Alloy Formed under Rapid Cooling via Laser Irradiation

〇Ryosuke Ozasa, Masayuki Okugawa, Kazuhisa Sato, Yuichiro Koizumi, Takayoshi Nakano

Hydrogen embrittlement behavior of Ni-based alloy fabricated by Laser-powder bed fusion

〇Ozkan Gokcekaya, Tatsuya Nitomakida, Takayoshi Nakano

Regulation of mesenchymal stromal cell differentiation by periodic grooved structures fabricated via metal additive manufacturing for the sustainable construction of oriented bone matrix

〇Tadaaki Matsuzaka, Aira Matsugaki, Takayoshi Nakano

【Poster】

Elimination of the 3DP-introduced specific microstructural features and isolation of their strengthening effects

〇Taichi Kikukawa, Takuya Ishimoto

Microstructure and Mechanical Properties in Ti-42Nb Alloy Developed via Laser-Powder Bed Fusion

〇Keitaro Miyasawa, Ryosuke Ozasa, Daisuke Egusa, Eiji Abe, Masakazu Tane, Takayoshi Nakano

Bone Matrix Anisotropy as a Novel Indicator of Osteoporosis-related Fragility

〇Taichi Isoya, Aira Matsugaki, Takayoshi Nakano

-

2025.12.4

【論文】Journal of Physics: Conference Seriesにレーザ粉末床溶融法で作製した β型Ti-Cr 合金における格子欠陥の陽電子消滅分光および第一原理計算による解析に関する論文が掲載されました。

Masataka Mizuno, Ryosuke Takahagi, Ryosuke Ozasa, Takayoshi Nakano, Hideki Araki:

Investigation of lattice defects in β-type Ti-Cr alloys fabricated via laser powder bed fusion using positron annihilation spectroscopy and first-principles calculations, Journal of Physics: Conference Series, 3149, (2025), 012010.

DOI: https://iopscience.iop.org/article/10.1088/1742-6596/3149/1/012010

論文はこちら

PDFはこちら

Abstract

The structure of β-type titanium alloys with a body-centered cubic (BCC) arrangement is stabilized by β-stabilizing elements. In the present study, to clarify the influence of β-stabilizing elements on the stability of lattice defects in β-type Ti-18.7 at%Cr alloys prepared by laser powder bed fusion (LPBF), the as-fabricated samples were subjected to positron lifetime measurements. The positron lifetime of the as-fabricated sample was approximately 20 ps longer than that of the annealed sample, indicating the introduction of lattice defects in the as-fabricated samples. The positron lifetime of the defect component in Ti-18.7%Cr fell between those of vacancies and dislocations, suggesting that both types of defects were introduced during LPBF fabrication. In contrast, in the authors' previous study, no lattice defects were observed in Ti-15Mo-5Zr-3Al, plausibly because of the recovery of vacancies during LPBF cooling. This recovery is attributed to the anomalously fast vacancy diffusion in the BCC β-phase. In the case of Ti-18.7 at%Cr, such vacancy recovery may be inhibited by the presence of Cr atoms, which tend to increase the energy for vacancy formation and migration at neighboring sites. -

2025.12.4

【書籍】中野先生と松垣先生が分担執筆した『界面制御による革新的生体適合性材料開発』が2025年12月15日に発刊されます。

高井まどか、三浦佳子、中野貴由、松垣あいら(分担):

界面制御による革新的生体適合性材料開発、株式会社エヌ・ティー・エス、2025年12月15日発刊、ISBN: 978-4-86043-782-4

https://www.nts-book.co.jp/item/detail/summary/bio/20251200_330.html -

2025.11.27

【受賞】第19回 物性科学領域横断研究会にて、M2の宮澤君が最優秀若手奨励賞を受賞しました。

レーザ粉末床溶融結合を利用した準安定β型Ti合金の窒素固溶化と高機能化

○宮澤 啓太郎、小笹 良輔、中野 貴由

最優秀若手奨励賞、東京大学、2025年11月27日 -

2025.11.25

【論文】ElsevierのBioactive Materials (IF=20.3)に水和水に基づく骨組織とハイドロキシアパタイトの接着に関する論文がOA論文として掲載されました。

Shichao Xie, Masahiro Okada*, Haruyuki Aoyagi, Akihisa Otaka, Xiaofeng Yang, Takayoshi Nakano, Takuya Matsumoto*:

Robust adhesion between solid-state hydroxyapatite and bone tissue through surface demineralization, Bioactive Materials, 57, (2026), 632-645.

DOI: https://doi.org/10.1016/j.bioactmat.2025.11.030

論文はこちら

PDFはこちら

Abstract

Objective Current bone adhesives typically lack adequate mechanical strength, long-term stability, or biocompatibility. To address these limitations, we designed a new adhesion strategy using a solid-state hydroxyapatite (HAp) adhesive in combination with bone surface demineralization.

Methods

Solid-state HAp adhesives were synthesized via wet chemical precipitation and heat treatment. Cortical bone specimens were partially demineralized with phosphoric acid (H3PO4) or ethylenediaminetetraacetic acid (EDTA), and characterized using scanning electron microscopy (SEM) and attenuated total reflectance-Fourier transform infrared spectroscopy (ATR-FTIR). Shear adhesion strength of HAp to demineralized bone was measured over time. In vivo fixation was assessed in rats using micro-computed tomography and histology. Statistical analysis used Tukey-Kramer tests after normality and variance checks.

Results

Although the HAp adhesive failed to adhere to non-demineralized bone, effective adhesion was achieved on the surface-demineralized bone tissue. Shear adhesion strength was significantly higher in EDTA-treated samples (238.4 kPa at 10 h) compared to H3PO4-treated samples (102.9 kPa at 1 h), with performance correlating with demineralization depth. ATR-FTIR and SEM analyses revealed that EDTA preserved collagen's triple-helix structure and free water content, both enhancing adhesion. Animal experiments confirmed stable fixation of HAp adhesive to demineralized bone tissue.

Conclusions

Surface demineralization enabled strong adhesion of the solid-state HAp adhesive to bone by exposing collagen swollen with water. Adhesion strength was influenced by structural changes in the demineralized layer, and the adhesive provided stable in vivo fixation, supporting its potential for bone-anchored biomedical applications. -

2025.11.19

【論文】ElsevierのBioactive Materials (IF=20.3)に水和水に基づく骨組織とハイドロキシアパタイトの接着に関する論文が受理され、OA論文として掲載予定です。

Shichao Xie, Masahiro Okada*, Haruyuki Aoyagi, Akihisa Otaka, Xiaofeng Yang, Takayoshi Nakano, Takuya Matsumoto*: Robust adhesion between solid-state hydroxyapatite and bone tissue through surface demineralization, Bioactive Materials, accepted, (2025).

-

2025.11.14

【冶金杯】令和七年度冶金杯ソフトボール大会で優勝しました。

-

2025.11.12

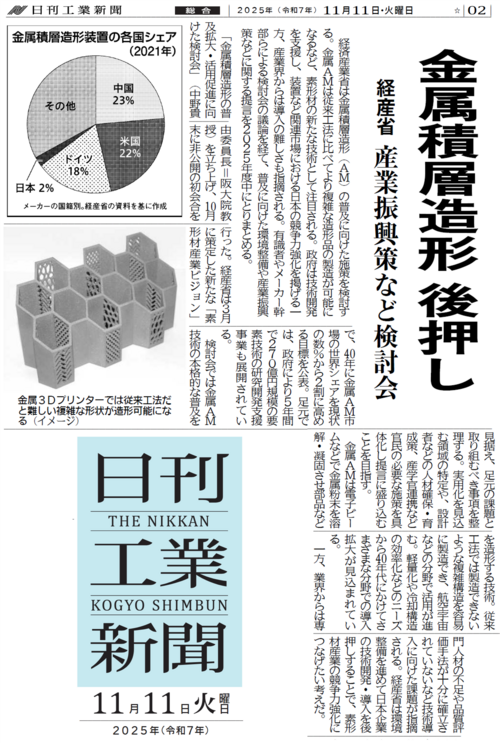

【新聞】日刊工業新聞に、経済産業省による「金属積層造形の普及拡大・活用促進に向けた検討会」の記事が11月11日に、JST-Crestの安田研を中心とした成果が11月12日に掲載されました。

-

2025.11.12

【委員会】経済産業省による非公開開催の「金属積層造形の普及拡大・活用促進に向けた検討会」の詳細が経済産業省のHPで公開されました。中野先生が委員長を務めています。第一回は2025年10月31日に開催されました。

検討委員会HP→

https://www.meti.go.jp/policy/mono_info_service/mono/sokeizai/AM-WG.html

第一回検討委員会(2025年10月31日)→https://www.meti.go.jp/policy/mono_info_service/mono/sokeizai/AM-WG01.html

★趣旨・目的

積層造形(以下、AM:Additive Manufacturing)は製造業に変革をもたらすと言われてきました。現時点でも、航空宇宙、医療機器、プロトタイプの試作、エネルギーなどの分野で、AMは既に商業的な利用が開始されるなど、AMの利用は拡大しています。

また、経済安全保障の観点でも、AMは、我が国の製造業の優位性、国際競争力を維持するための「ものづくり基盤技術」の一つとして期待されています。

こうした状況を踏まえ、次の点を中心に現状の取組を整理した上で、AMの普及拡大・活用促進に向けて取り組むべき事項に関して検討を行い、具体的な提言を取りまとめる予定です。

AMの価値・可能性

AM人材の確保・強化

AMの技術進展、コスト低減

AMに関する産学連携の強化(地域拠点化を含む)

技術基盤(品質保証・認証制度等)の整備と促進

AMの認知度向上(AM活用事例を含む) -

2025.11.12

【学会主催】中野先生が大会長を務める第48回日本バイオマテリアル学会大会のHPが掲載されました。

第48回日本バイオマテリアル学会大会の大会長を拝命し、2026年11月9日(月)~10日(火)の期間、神戸国際会議場(〒650-0046 神戸市中央区港島中町6-9-1)にて開催することになりました。

今回の大会のテーマは「バイオマテリアル イノベーション~「知」の未来実装~」と致しました。使われてこそ"バイオマテリアル"との考えのもと、バイオマテリアルに対して、より高度で精密な機能性の発揮が求められています。バイオマテリアル関連研究者・技術者・臨床家の絶え間ない「知」への挑戦が、より高い次元での社会実装へとつながるものと確信しています。多数の皆様、奮ってご参加ください。

リンク→https://lynx-dent.jp/jsb48/

ポスター→final_48バイオ.pdf -

2025.11.11

【論文・プレスリリース】大阪大学から、「金属3D プリンティングに特異な高強度階層組織の変形挙動を解明」に関するActa Materialiaへの論文掲載に関するプレスリリースを14時付で行いました。同時に論文がOAとして掲載されました。JST-Crestの成果です。

Ken Cho, Kippei Yamashita, Shinnosuke Kakutani, Takuma Saito, Taisuke Sasaki, Katsuhiko Sawaizumi, Masayuki Okugawa, Yuichiro Koizumi, Tsuyoshi Mayama, Taichi Kikukawa, Ozkan Gokcekaya, Takuya Ishimoto, Hajime Kimizuka, Wu Gong, Takuro Kawasaki, Stefanus Harjo, Takayoshi Nakano, Hiroyuki Y. Yasuda*: Effect of nanoscale cellular structure on the mechanical properties of Inconel 718 with unique hierarchical structure fabricated by laser powder bed fusion, Acta Materialia.

DOI: https://doi.org/10.1016/j.actamat.2025.121696

プレスリリース原稿はこちら

論文はこちら

Abstract

The deformation behavior and strengthening mechanism of Inconel 718 with a hierarchical structure composed of microscale crystallographic lamellar microstructure (CLM) and nanoscale cellular structure, fabricated by laser powder bed fusion, were clarified via nanoscale microstructural and in-situ neutron diffraction analyses. The CLM is a layered structure parallel to the building direction (BD) and consists of relatively wide main and narrow sub-layers with <110> and <100> orientations, respectively, with respect to BD. This is the first study to demonstrate that the yield stress of the alloys depends strongly on deformation stresses of the sub-layers, even though Schmid factors of the primary slip system for both layers are the same. The sub-layer continues to deform elastically even beyond the micro-yield point of the main layer, which results in the macroscopic strengthening at an early stage of deformation. On the other hand, the cellular structure is formed in both layers, associated with a dendritic cell growth along <100> direction, Nb segregation between the cells and an accumulation of dislocations to decrease a residual stress. The cell boundaries with numerous dislocations and Nb segregation act as a strong barrier to dislocation motion resulting in a stress increase through the Hall-Petch law, even though they are low-angle grain boundaries. The spacing and morphology of the cell boundary depend strongly on fabrication conditions. The optimized cellular structure provides significant strengthening comparable to or greater than that caused by large-angle grain boundaries, thereby increasing the macroscopic strength of the alloys through hardening of the sub-layer. -

2025.11.10

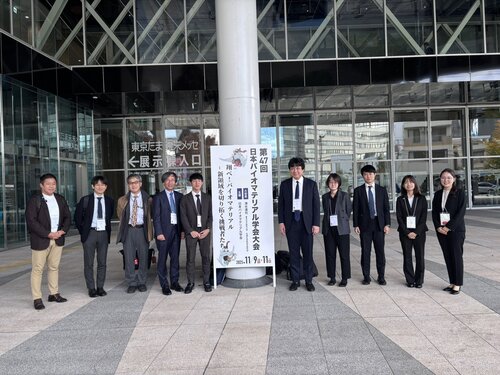

【学会】第47回日本バイオマテリアル学会大会(@東京たま未来メッセ、11月10日~11月11日)に参加しました。

【日本学術会議公開シンポジウム】

骨基質配向化デバイスの創製

〇中野貴由

固体表面機能創出・界面バイオ反応制御

〇松垣あいら

【一般講演】

マイクロパターンMPC-Ti材料による骨芽細胞配列を介した機能的骨組織再生

〇松坂匡晃、松垣あいら、石原一彦、中野貴由

薬剤性骨脆弱化における骨基質タンパク質活性制御と骨配向性の変化

〇齊藤光郁、松垣あいら、中野貴由

材料表面形状により配向制御した骨芽細胞・骨基質の抗菌特性発現

〇森陶子、松垣あいら、中野貴由

硬組織に対する多孔質ハイドロキシアパタイトの接着固定

○謝世超、岡田正弘、青柳陽之、大高晋之、楊暁峰、中野貴由、松本卓也

【ポスター】

酸処理チタンと骨との相互作用に関する研究

〇青柳陽之、大高晋之、岡田正弘、中野貴由、松本卓也

左から関西大 上田正人先生、関西大 岩﨑泰彦先生、東京理科大 菊池明彦先生、大阪大学 石原一彦先生とともに

閉会式では、来年度の第48回日本バイオマテリアル学会大会に向けて、大会長としての決意を述べました。

-

2025.11.10

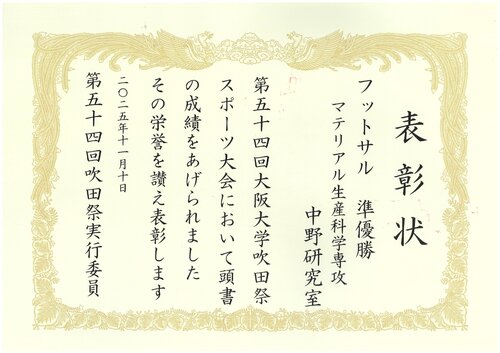

【吹田祭】第五十四回大阪大学吹田祭スポーツ大会のフットサルで準優勝しました。

-

2025.11.10

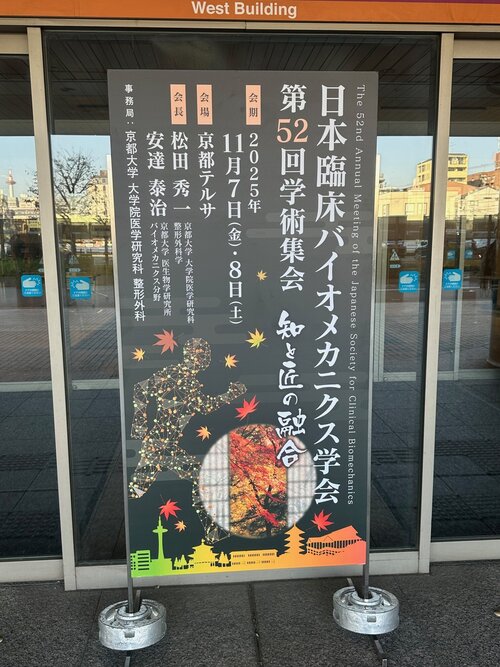

【特別講演】中野先生が、日本臨床バイオメカニクス学会第52回学術集会(松田秀一会長・安達泰治会長)にて特別講演をしました。

-

2025.11.8

【招待講演】松垣先生が、日本臨床バイオメカニクス学会第52回学術集会(松田秀一会長・安達泰治会長)にて招待講演を行いました。

松垣あいら、松坂匡晃、中野貴由:骨マトリクス形成における骨細胞メカノバイオロジー、日本臨床バイオメカニクス学会第52回学術集会(松田秀一会長・安達泰治会長)、シンポジウム「運動器の細胞・組織メカノバイオロジー」、2025年11月8日(土)、京都テルサ.

-

2025.11.7

【論文】経口投与されたリン酸カルシウムによるカドミウム誘発性骨劣化の改善効果に関する研究成果が、Biological Trace Element Research にOA論文として掲載されました。

Ping-chin Sung, Ahmad Bikharudin, Masahiro Okada, Randa Musa, Kenta Uchida, Akihisa Otaka, Tadaaki Matsuzaka, Aira Matsugaki, Takayoshi Nakano, Takuya Matsumoto:

Amelioration of Cd-induced Bone Deterioration by Orally Administered Calcium Phosphate, Applied Food Research, 5, (2025), 101482: 1-9.

DOI: https://doi.org/10.1016/j.afres.2025.101482

論文はこちら

PDFはこちら

Abstract

Cadmium (Cd) is a heavy metal that accumulates in the body, primarily through daily grain intake, and has a high affinity for bone, leading to skeletal diseases such as osteomalacia and fractures. Hydroxyapatite (HAp), a major bone mineral component, is highly pH-sensitive and is known to incorporate Cd, as observed in studies of Itai-itai disease. Based on these findings, we hypothesized that HAp could serve as an effective oral detoxification material for heavy metals. This study investigated the efficacy of orally administered HAp in inhibiting Cd-induced changes in bone physical and chemical properties, comparing its effects to those of activated charcoal (AC), a common detoxifying agent. Six-week-old male ICR mice were exposed to cadmium via drinking water containing CdCl2 and subsequently given diets containing either HAp or AC for four weeks. Three-point bending tests, micro-CT analysis, and histological observations of the femurs demonstrated that mice receiving HAp exhibited improved mechanical strength and enhanced bone quality protection compared to the control and other Cd-treated groups. Activated charcoal also contributed to bone quality improvement at low concentrations, but its effect diminished at high concentrations. These results suggest that the oral administration of HAp may be a promising therapeutic strategy for suppressing cadmium-induced osteomalacia. -

2025.11.6

【論文】経口投与されたリン酸カルシウムによるカドミウム誘発性骨劣化の改善効果に関する研究成果が、Biological Trace Element Research へ受理されました。

Ping-chin Sung, Ahmad Bikharudin, Masahiro Okada, Randa Musa, Kenta Uchida, Akihisa Otaka, Tadaaki Matsusaka, Aira Matsugaki, Takayoshi Nakano, Takuya Matsumoto:

Amelioration of Cd-induced Bone Deterioration by Orally Administered Calcium Phosphate, Applied Food Research, (2025), 101482. -

2025.11.2

【論文】Ni基超合金の摩耗・腐食特性への組織の影響について、Journal of Materials Research and Technology にOA論文として掲載されました。

Sung-Hyun Park, Fatmanur Ayten, Asli Gunay Bulutsuz, Ozkan Gokcekaya*, Muhammed Enes İlgazi, Hakan Yilmazer, Burak Dikici, Takayoshi Nakano*:

Wear and corrosion performance of textured Hastelloy-X fabricated by laser powder bed fusion: Process window and microstructural features, Journal of Materials Research and Technology, 39, (2025), 6156-6168.

DOI: https://doi.org/10.1016/j.jmrt.2025.10.229

論文はこちら

PDFはこちら

Abstract

This study investigated the effect of volumetric energy density (VED) on the densification and microstructural evolution of Hastelloy-X (HX) alloy fabricated by the laser powder bed fusion (L-PBF) process, and how these changes affect wear and corrosion performance. Variations in VED altered melt pool geometries, which influenced densification. In addition, VED also affected the growth direction of <100> cellular microstructures, resulting in different crystallographic texture development. Specifically, high VED showed the lowest densification with strong <100> alignment in x,y, and z directions. Meanwhile, medium VED exhibited the highest densification with a mixed <100> and <110> crystallographic texture along the building direction, while low VED led to moderate densification with weak <100> alignment overall. The wear and corrosion properties of the samples varied with their densification and microstructural characteristics. In terms of wear mechanisms, a distinct load dependence was observed. Oxidative wear dominated at low loads, where the strong (100)-oriented crystallographic texture promoted oxide stability and improved the wear resistance. While deformation wear prevailed at higher loads, where hardness became the determining factor. As for corrosion resistance, higher densification, grain refinement, and high dislocation density generally facilitated passive film formation and improved resistance. However, crystallographic texture should also be considered, since (100)-oriented regions are more prone to corrosion than other orientations, indicating that the crystallographic texture inherent to L-PBF processing is an important factor in corrosion behavior. The results demonstrate that optimizing L-PBF process parameters is essential for tailoring microstructure and improving the wear and corrosion resistance of Ni-based superalloys. -

2025.11.1

【受賞】日本金属学会第8回第7分野講演会にて、M2の清水君、M1の時實君が優秀ポスター賞を受賞しました。

L-PBF法により創製される温度場を介したインバー合金の低熱膨張化

○清水佑太、Ozkan Gokcekaya、小笹良輔、寺井智之、蓮見侑士、大山伸幸、中野貴由

第8回日本金属学会第7分野講演会最優秀ポスター賞、神戸大学、2025年11月1日

下顎骨における咀嚼荷重に応じた三次元的な骨配向性変化

○時實秀和、松坂匡晃、松垣あいら、中野貴由

第8回日本金属学会第7分野講演会最優秀ポスター賞、神戸大学、2025年11月1日 -

2025.11.1

【学会】中野研究室のメンバーが第8回日本金属学会第7分野講演会「⾦属系バイオマテリアルサイエンスの新展開(Ⅷ)」(@神戸大学、11月1日)に参加しました。

11月1日

ポスター発表

L-PBF法により創製される温度場を介したインバー合金の低熱膨張化

○清水佑太、Ozkan Gokcekaya、小笹良輔、寺井智之、蓮見侑士、大山伸幸、中野貴由

下顎骨における咀嚼荷重に応じた三次元的な骨配向性変化

○時實秀和、松坂匡晃、松垣あいら、中野貴由 -

2025.10.29

【招待講演】松垣先生が、粉体粉末冶金協会 2025年度秋季大会(第136回講演大会)にて招待講演を行いました。

松垣あいら、小笹良輔、Gokcekaya Ozkan:レーザ粉末床溶融結合法による生体用ハイエントロピー合金の新規開発に関する研究、粉体粉末冶金協会 2025年度秋季大会(第136回講演大会) 協会賞受賞記念講演(研究進歩賞) 九州大学医学部 百年講堂、2025年10月29日

-

2025.10.28

【論文】Ni基超合金の摩耗・腐食特性への組織の影響について、Journal of Materials Research and Technologyへ受理されました。

Sung-Hyun Park, Fatmanur Ayten, Asli Gunay Bulutsuz, Ozkan Gokcekaya*, Muhammed Enes İlgazi, Hakan Yilmazer, Burak Dikici, Takayoshi Nakano*:

Wear and corrosion performance of textured Hastelloy-X fabricated by laser powder bed fusion: Process window and microstructural features, Journal of Materials Research and Technology, 39, (2025), 6156-6168. -

2025.10.16

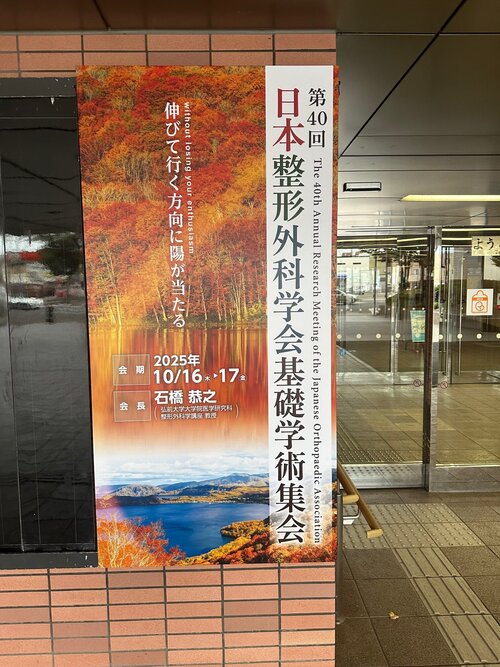

【招待講演】中野先生が第40回日本整形外科学会基礎学術集会(石橋恭之会長、青森)で招待講演を行いました。

-

2025.10.9

【受賞】宮澤君が、日本チタン学会 講演大会(2025年度)(直江津)にて、最優秀ポスター賞を受賞しました。

宮澤啓太郎、小笹良輔、中野貴由:

最優秀ポスター賞、L-PBFにおける窒素ガス雰囲気を利用したTi-42Nb合金の高強度化、

第5回日本チタン学会講演大会(2025年度)、日本チタン学会、

2025年10月10日、直江津学びの交流館 -

2025.10.9

【学会】第5回日本チタン学会 講演大会(2025年度)(@直江津学びの交流館、10月9,10日)に参加し、以下の発表を行いました。

-

2025.9.29

【講演】中野先生がセラミックス3D積層造形研究会 2025年度第1回研究会にて講演を行いました。

中野貴由先生が、一般社団法人日本ファインセラミックス協会にて開催された「セラミックス3D積層造形研究会 2025年度第1回研究会」において、 「結晶性材料の積層造形による形状・結晶配向性制御と骨医療デバイス応用」 と題したご講演を行いました。

PDFはこちら -

2025.9.26

【受賞】日本金属学会2025年(第177回)秋期講演大会ポスターセッションにて、M1の竹下君、M2の内芝君が優秀ポスター賞を受賞しました。

特異な直交性⾻基質配向化制御機構の解明と⽣体組織配向性への影響

○⽵下 恭平、中⻄ 陽平、松坂 匡晃、松垣 あいら、中野 貴由

第45回優秀ポスター賞、北海道大学、2025年9月17日

レーザ粉末床溶融結合を⽤いたTi準結晶の創製と組織解析

○内芝 旭祥、⼩笹 良輔、佐藤 和久、中野 貴由

第45回優秀ポスター賞、北海道大学、2025年9月17日 -

2025.9.24

【お祝い】中野研究室のメンバーで中野先生の58歳の誕生日をお祝いしました。

-

2025.9.23

【論文編集】中野先生がAdditive Manufacturingをはじめとした材料開発と新プロセスに関する新規の論文誌、"Journal of Innovations in Materials and Manufacturing Engineering (JIMME)" の編集委員に就任しました。オーストラリアのScilight Pressから出版され、チーフエディターはテキサス大のProf. L. E. Murrです。

中野先生がAdditive Manufacturingをはじめとした材料開発と新プロセスに関する新規の論文誌、"Journal of Innovations in Materials and Manufacturing Engineering (JIMME)" の編集委員に就任しました。オーストラリアのScilight Pressから出版され、チーフエディターはテキサス大のProf. L. E. Murrです。

AIMS

Journal of Innovations in Materials and Manufacturing Engineering (JIMME) is an international, peer-reviewed, multidisciplinary journal that provides a platform for disseminating high-quality original research and critical reviews in materials and manufacturing engineering. The journal serves both the academic and industrial communities, fostering the exchange oof cutting-edge knowledge and innovations. It aims to highlight contemporary advances and future developments, with particular emphasis on the practical applications of novel materials and manufacturing technologies. It is published quarterly online by Scilight Press, Melbourne, Australia.

Scope of the Journal

JIMME covers a broad range of topics encompassing new materials, processes, and technologies applied to manufacturing engineering and product development, with special focus on innovations in additive manufacturing and related emerging processes. Topics of interest include, but are not limited to:

• Novel materials development, synthesis, applications, and methodologies in advanced manufacturing processes, particularly across the full spectrum of 3D printing technologies.

• Multifunctional material and device design, covering metals and alloys (including high-entropy alloys, superalloys, and superplastic alloys), composite materials, electronic and optical materials, nanomaterials, biomaterials, 2D materials, and other advanced material systems.

• Innovations in materials processing, including hybrid and multi-material manufacturing approaches.

• Characterization, optimization, and simulation of materials and manufacturing processes, with an emphasis on modelling, artificial intelligence-driven design, and digital manufacturing applications -

2025.9.17

【学会】日本金属学会2025年(第177回)春期講演大会(@北海道大学、9月17日~9月19日)に参加しています。

-

2025.9.17

【学会】中野研究室のメンバーが日本金属学会2025年(第177回)春期講演大会(@北海道大学、9月17日~9月19日)に参加します。

9月17日

〇小笹良輔、中野貴由:

[S5.28] [基調講演] L-PBFにより創製したBCC型Ti含有合金の急冷凝固組織

〇重永 徹平、松坂 匡晃、松垣 あいら、中野 貴由:

[P127] PBF-LB法による高分子材料中の高次組織配向制御

〇山野 大陸、山田 夏子、松垣 あいら、石本 卓也、中野 貴由:

[P129] ヒト頭蓋骨における階層的な異方性骨微細構造の解明

〇竹下 恭平、中西 陽平、松坂 匡晃、松垣 あいら、中野 貴由:

[P312] 特異な直交性骨基質配向化制御機構の解明と生体組織配向性への影響

〇平田 渉悟、小笹 良輔、石本 卓也、佐藤 和久、今野 晋也、石田 清仁、中野 貴由:

[P315] L-PBFによる炭化物析出強化型Co基超合金の微細組織制御と力学特性

〇内芝 旭祥、小笹 良輔、佐藤 和久、中野 貴由:

[P321] レーザ粉末床溶融結合を用いたTi準結晶の創製と組織解析

9月18日

〇松坂 匡晃、田中 謙次、大原 秀真、松垣 あいら、中野 貴由:

159 OCNの翻訳後修飾による耳小骨配向性制御と聴覚機能維持機構の解明

〇松垣 あいら、渡邊 稜太、中野 貴由:

160 慢性炎症モデルにおける骨基質配向性変化と感染抵抗性への影響

〇宮澤 啓太郎、小笹 良輔、中野 貴由:

[S5.30] レーザ粉末床溶融結合における窒素雰囲気ガスがTi-42Nb合金の微細組織と力学特性に及ぼす影響

9月19日

〇ゴクチェカヤ オズカン、中野 貴由:

186 Hydrogen embrittlement behavior of Ni-based alloy fabricated by laser powder bed fusion

〇菊川 泰地、石本 卓也、眞山 剛、中野 貴由:

[S5.37] L-PBF を利用した Ni 基合金への人工界面構造導入による高強度化の体系的理解

〇星野 壮希、石本 卓也、Gokcekaya Ozkan、眞山 剛、多根 正和、中野 貴由:

[S5.38] PBF-LB/Mを用いた形状・結晶方位制御によるNi基IN718の力学機能設計 -

2025.9.12

【報道】9月11日の産総研・中部大学・大阪大学・名古屋工業大学からのプレスリリースを受けて、多数の報道がなされました。

9月11日の産総研・中部大学・大阪大学・名古屋工業大学からのプレスリリースを受けて、多数の報道がなされました。

★日刊工業新聞

★Newsウェーブ21

★共同通信

★下野新聞

★沖縄タイムス+

★北海道新聞デジタル

★秋田魁新報社

★FM FUKUOKA

★山梨日日新聞デジタル -

2025.9.11

【プレスリリース】Advanced Healthcare Materialsの研究論文掲載に関して、産総研・中部大・大阪大・名古屋工業大からプレスリリースがされました。

Sungho Lee*, Hayato Asano, Makoto Sakurai, Takayoshi Nakano, and Toshihiro Kasuga:

Preparation of Bifunctional Orthosilicophosphate MgO-CaO-ZnO-P₂O₅-SiO₂ Glasses: in vitro Evaluation of Antibacterial Activity and Osteoblast Gene Expression Behavior, Advanced Healthcare Materials, (2025), e02546; 1-11.

DOI: https://doi.org/10.1002/adhm.202502546

プレスリリースはこちら -

2025.9.9

【行事】毎年恒例の研究室旅行を行い大いに盛り上がりました。

-

2025.9.6

【論文】Advanced Healthcare Materialsに、リン酸塩系バイオガラスの抗菌性と骨芽細胞応答に関する研究論文がOA論文として掲載されました。

Sungho Lee*, Hayato Asano, Makoto Sakurai, Takayoshi Nakano, and Toshihiro Kasuga:

Preparation of Bifunctional Orthosilicophosphate MgO-CaO-ZnO-P₂O₅-SiO₂ Glasses: in vitro Evaluation of Antibacterial Activity and Osteoblast Gene Expression Behavior, Advanced Healthcare Materials, (2025), article number e02546.

DOI: https://doi.org/10.1002/adhm.202502546

論文はこちら

PDFはこちら

Abstract

Phosphate and phosphate invert glasses contain various elements, with a wide range of compositions. Recently, our group reported orthosilicophosphate glasses (SPGs) and the glass network structure composed of orthophosphates and orthosilicates crosslinked by cations. ZnO is an intermediate oxide that improves the chemical durability of glass. Additionally, Zn2+ ions exhibit antibacterial activity and stimulate bone formation. In this work, ZnO-containing SPGs are prepared for biomedical applications. The glasses are mainly composed of PO4, SiO4, MgO4, and ZnO4 orthotetrahedral structures. The ZnO-containing SPGs exhibit excellent antibacterial activity, with bacterial counts > 5 orders of magnitude lower than that of the control. Meanwhile, ZnO-containing SPGs have mild inhibitory effects on cell proliferation by Zn2+ ions; however, they exhibit significant upregulation of osteogenic markers compared with the control owing to the release of inorganic ions from the glasses. The ZnO-containing SPGs prepared in this work exhibit bifunctional properties suitable for biomedical applications. They serve as bioadaptive materials capable of controlling gene expression by releasing therapeutic ions. -

2025.9.5

【研究会】JST-Crestナノ力学のチーム内(大阪大・東京大・熊本大・名古屋大)対面会議を大阪府で開催しました。

-

2025.9.5

第67回歯科基礎医学会学術大会で講演を行いました。

-

2025.9.3

【受賞】日本AM学会第一回講演大会で中野研関連のポスタープレゼンテーションが優秀ポスター賞を受賞しました。

塑性ひずみ不適合界面の導入によるマグネシウム合金の高強度化に関する結晶塑性解析

○山口貴央、眞山剛、小笹良輔、中野 貴由

日本AM学会第1回講演大会優秀ポスター賞、東京都立産業貿易センター浜松町館、2025年9月3日

L-PBF法を活用した形状と異方性 / 等方性材質の頂上によるIN718のカスタム力学機能設計

○星野壮希、石本卓也、Ozkan Gokcekaya、眞山剛、多根正和、中野貴由

日本AM学会第1回講演大会優秀ポスター賞、東京都立産業貿易センター浜松町館、2025年9月3日

Na2Ti3O7-supported Ru catalyst: ambient CO2 methanation and application in 3D reactor

○Takayoshi Nakano, Hiromi Yamashita, Kohsuke Mori

日本AM学会第1回講演大会優秀ポスター賞、東京都立産業貿易センター浜松町館、2025年9月3日 -

2025.9.3

【新聞】日刊工業新聞に日本AM学会第一回講演大会の様子が掲載されました。

-

2025.9.3

【学会】日本Additive manufacturing学会 第一回講演大会(@東京都立産業貿易センター浜松町館、9月1日~9月3日)が開催されました。

750名以上が参加し、大変好評に終わりました。中野先生が会長を務め、中野研の皆が総動員でお手伝いし、500名以上が参加する大盛況な会に終わりました。

★日本AM学会講演大会の様子→

https://ji-am.jp/2025/09/1stannualmeeting_all/

★講演大会のプログラム→

https://ji-am.jp/2025/05/1stannualmeeting1/

★中野研の発表

9月2日

シンポジウム

〇中野 貴由:

[S5.1] カスタム力学機能制御学の構築~階層化異方性骨組織に学ぶ~

〇小笹 良輔:

[S6.2] L-PBFと合金設計を活用した金属材料の微細組織制御

9月3日

一般公演

〇松坂 匡晃、松垣 あいら、中野 貴由:

[19] 金属AMによる周期的溝構造を介した間葉系間質細胞の骨分化誘導

〇Ozkan Gokcekaya・Tatsuya Nitomakida・Takayoshi Nakano:

[27] Hydrogen embrittlement behavior of Ni-based alloys through microstructural control by L-PBF method

〇熊谷 祥希、大同特殊鋼 髙橋 茉莉、小柳 禎彦、阪大 小笹 良輔、中野 貴由

[37]レーザ粉末床溶融結合法の造形過程におけるマルエージング鋼の変形挙動

ポスターセッション

〇重永 徹平、松坂 匡晃、松垣 あいら、中野 貴由:

[P3] PBF-LB法を用いた半結晶性高分子材料の高次組織配向制御

〇内芝 旭祥、小笹 良輔、佐藤 和久、中野 貴由:

[P19] レーザ粉末床溶融結合を用いた超急冷凝固によるTi基準結晶の創製

〇清水 佑太、Ozkan Gokcekaya、小笹 良輔、寺井 智之、蓮見 侑士、大山 伸幸、中野 貴由:

[P24] L-PBF法を介したインバー合金の低熱膨張化

〇平田 渉悟、小笹 良輔、石本 卓也、佐藤 和久、今野 晋也、石田 清仁、中野 貴由:

[P28] 析出強化型Co基超合金のL-PBF造形と微細組織

〇菊川 泰地、石本 卓也、眞山 剛、中野 貴由:

[P32] L-PBFによるNi基合金の界面設計と高強度化

〇宮澤 啓太郎、小笹 良輔、中野 貴由:

[P33] L-PBF法で作製されたNi基超合金中の微細組織が疲労挙動に及ぼす影響

〇星野 壮希、石本 卓也、Ozkan Gokcekaya、眞山 剛、多根 正和、中野 貴由:

[P35] L-PBF法を利用した形状と異方性/等方性材質の重畳によるIN718のカスタム力学機能設計 会場の様子

会場の様子 -

2025.9.2

【新聞】日刊工業新聞に日本AM学会第一回講演大会の様子が掲載されました。

-

2025.9.1

【解説・論文】中野先生が特集したスマートプロセス学会誌「AM技術の進展と応用(Ⅱ)」が発行され、中野研関係の解説と論文が掲載されました。

中野先生が特集したスマートプロセス学会誌「AM技術の進展と応用(Ⅱ)」が発行され、中野研関係の解説と論文が掲載されました。

Vol. 14[No. 5]、2025(令和 7 年 9 月)、AM技術の進展と応用(Ⅱ)、スマートプロセス学会誌

【解説】

★桐原聡秀、中野貴由:巻頭「AM技術の進展と応用(Ⅱ)」、 スマートプロセス学会誌、14[5], (2025), pp.199. ★小泉雄一郎、奥川将行、柳玉恒、中野貴由:新材料創製のための粉末床溶融結合式付加製造のデジタルツイン科学、 スマートプロセス学会誌、14[5], (2025), pp.200-207.

★石本卓也、中野貴由:金属AMによる異方性機能設計―形状と結晶配向の重畳、 スマートプロセス学会誌、14[5], (2025), pp.221-226.

★小笹良輔、Gokcekaya Ozkan、中野貴由:レーザ粉末床溶融結合によるBCC型ハイエントロピー合金のin-situ合金化、 スマートプロセス学会誌、14[5], (2025), pp.243-248.

【研究論文】

★松坂匡晃、小坂朋生、山野大陸、船奥和真、劉甜、松垣あいら、中野貴由:生体用AMインプラント材料の抗菌特性評価のためのin vitro 共培養モデルの構築、 スマートプロセス学会誌、14[5], (2025), pp.249-252.

★小笹良輔、Kim Yong Seong、朝倉光平、堀尾尚平、鰐渕良祐、中野貴由:金属3Dプリンタ用レーザ照射による非等量Ti-Nb-Mo-Ta-W系ハイエントロピー合金の組織形成挙動、 スマートプロセス学会誌、14[5], (2025), pp.253-257.

★宮澤啓太郎、小笹良輔、内芝旭祥、清水佑太、中野貴由:L-PBF で造形した準安定β型Ti合金におけるヤング率の変化、 スマートプロセス学会誌、14[5], (2025), pp.258-263. -

2025.8.22

【行事】中野研の院試お疲れ様会を行いました。

-

2025.8.22

【論文】産総研や名工大との共同研究によるバイオガラスによるZnの徐放による骨質の向上に関する研究成果がAdvanced Healthcare Materialsに受理されました。9月9日に出版される予定です。

Sungho Lee*, Hayato Asano, Makoto Sakurai, Takayoshi Nakano, and Toshihiro Kasuga:

Preparation of Bifunctional Orthosilicophosphate MgO-CaO-ZnO-P₂O₅-SiO₂ Glasses: in vitro Evaluation of Antibacterial Activity and Osteoblast Gene Expression Behavior,

Advanced Healthcare Materials, (2025), in press. -

2025.8.6

【論文】Materials Today CommunicationsにTi合金の酸化抑制に関する中国東北大との共同研究論文が掲載されました。

Yiming Jin, Jiani Li, Takayoshi Nakano, Hideki Hosoda, Mitsuo Niinomi, Xiaowei Zhang, Deliang Zhang, Xiaoli Zhao*:

Zr-Enhanced Ambient-Air Thermal Oxidation of Ti-30Zr-5Mo Alloy Using Low Tβ for Implants, Materials Today Communications, (2025), Volume 48, 113442.

DOI: https://doi.org/10.1016/j.mtcomm.2025.113442

論文はこちら

PDFはこちら

Abstract

Metastable β-Ti alloy Ti-30Zr-5Mo (Tβ ≈ 700 °C) offers low modulus, biocompatibility, and strength for spinal rod implants but has limited hardness (280 Hv) and wear resistance. Conventional surface treatments like vacuum-based physical vapor deposition (PVD), are costly and complex. This study exploits the low Tβ and high Zr content (30 wt.%) of Ti-30Zr-5Mo alloy for single-step, ambient-air thermal oxidation at 600-700 °C, combining heat treatment with surface modification. The low Tβ ensures controlled oxidation, preventing over-oxidation, while Zr's selective oxidation forms a dense ZrO2-rich layer, which is harder than TiO2, enhancing surface hardness. Spontaneous tetragonal to monoclinic phase transitions in ZrO2 further improve toughness. The resulting 5 μm-thick oxide layers exhibit a threefold hardness increase (904 Hv vs. 280 Hv), a surface roughness of 0.30 μm (suitable for osseointegration), strong interfacial adhesion (critical load: 43 N), and an 18-fold reduction in corrosion current density (from 1.62×10-7 to 8.96×10-9 A·cm-2). Despite minor microcracks, the layers maintain structural integrity, offering exceptional durability. This atmosphere-free approach provides a scalable solution for orthopedic and dental implants, combining mechanical durability with biological integration. The insights into Zr-driven oxidation dynamics at low Tβ could inform vacuum-based processes, when controlled oxygen partial pressure might further optimize oxide layer properties, aligning with advancement in surface technology. -

2025.8.1

超温度場材料創成学―AMを中心とした巨大ポテンシャル勾配による新材料創製

小泉雄一郎、足立吉隆、森下浩平、佐藤和久、戸田佳明、石本卓也、木村禎一、中野貴由:

超温度場材料創成学―AMを中心とした巨大ポテンシャル勾配による新材料創製、

AMフューチャー、1[2]、(2025)、pp.195-198. -

2025.8.1

2025年8月【解説】日本Additive Manufacturing学会誌のAMフュチャー「AMプロジェクト」(Vol. 1[No. 2]、2025(令和7年8月))が発行され、中野研関連解説が発行されました。

【解説】

日本Additive Manufacturing学会誌のAMフュチャー「AMプロジェクト」(Vol. 1[No. 2]、2025(令和7年8月))が発行され、中野研関連解説が発行されました。

Vol. 1[No. 2]、2025(令和7年8月)、AMフュチャー

★中野貴由、阿部英司、眞山剛、石本卓也:CREST ナノ力学―金属3Dプリンティングによるカスタム力学機能制御、 AMフュチャー、1[2]、(2025)、pp.191-194.

★小泉雄一郎、足立吉隆、森下浩平、佐藤和久、戸田佳明、石本卓也、木村禎一、中野貴由:超温度場材料創成学―AMを中心とした巨大ポテンシャル勾配による新材料創製、 AMフュチャー、1[2]、(2025)、pp.195-198. ★森浩亮、金孝鎮、中野貴由:炭素循環社会に貢献する金属AM触媒、 AMフュチャー、1[2]、(2025)、pp.219-222. -

2025.8.1

【行事】M2の皆さんの就職内々定お祝い会を行いました。

-

2025.7.29

【論文】Materials Today CommunicationsにTi合金の酸化抑制に関する中国東北大との共同研究論文が出版されました。

Yiming Jin, Jiani Li, Takayoshi Nakano, Hideki Hosoda, Mitsuo Niinomi, Xiaowei Zhang, Deliang Zhang, Xiaoli Zhao*:

Zr-Enhanced Ambient-Air Thermal Oxidation of Ti-30Zr-5Mo Alloy Using Low Tβ for Implants, Materials Today Communications, (2025), 113442.

DOI: https://doi.org/10.1016/j.mtcomm.2025.113442

論文はこちら

Abstract

Metastable β-Ti alloy Ti-30Zr-5Mo (Tβ ≈ 700 °C) offers low modulus, biocompatibility, and strength for spinal rod implants but has limited hardness (280 Hv) and wear resistance. Conventional surface treatments like vacuum-based physical vapor deposition (PVD), are costly and complex. This study exploits the low Tβ and high Zr content (30 wt.%) of Ti-30Zr-5Mo alloy for single-step, ambient-air thermal oxidation at 600-700 °C, combining heat treatment with surface modification. The low Tβ ensures controlled oxidation, preventing over-oxidation, while Zr's selective oxidation forms a dense ZrO2-rich layer, which is harder than TiO2, enhancing surface hardness. Spontaneous tetragonal to monoclinic phase transitions in ZrO2 further improve toughness. The resulting 5 μm-thick oxide layers exhibit a threefold hardness increase (904 Hv vs. 280 Hv), a surface roughness of 0.30 μm (suitable for osseointegration), strong interfacial adhesion (critical load: 43 N), and an 18-fold reduction in corrosion current density (from 1.62×10-7 to 8.96×10-9 A·cm-2). Despite minor microcracks, the layers maintain structural integrity, offering exceptional durability. This atmosphere-free approach provides a scalable solution for orthopedic and dental implants, combining mechanical durability with biological integration. The insights into Zr-driven oxidation dynamics at low Tβ could inform vacuum-based processes, when controlled oxygen partial pressure might further optimize oxide layer properties, aligning with advancement in surface technology.

Keywords

Ti-30Zr-5Mo alloy; Thermal oxidation; Oxidation mechanism; Internal oxidation; Surface modification -

2025.7.28

【論文】Materials Today CommunicationsにTi合金の酸化抑制に関する中国東北大との共同研究論文が受理されました。

Yiming Jin, Jiani Li, Takayoshi Nakano, Hideki Hosoda, Mitsuo Niinomi, Xiaowei Zhang, Deliang Zhang, Xiaoli Zhao*:

Zr-Enhanced Ambient-Air Thermal Oxidation of Ti-30Zr-5Mo Alloy Using Low Tβ for Implants, Materials Today Communications, (2025), in press -

2025.7.18

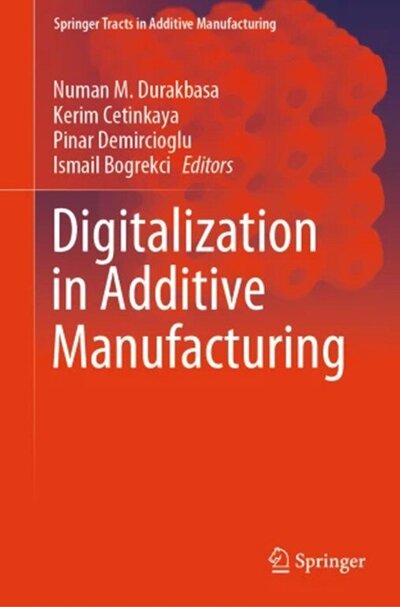

【書籍】Digitalization in Additive Manufacturing(Edited by Numan M. Durakbasa, Kerim Cetinkaya, Pinar Demircioglu, Ismail Bogrekci)が出版されました。

Gizem Coskun, Muhammed Enes Ilgazi, Asli Gunay Bulutsuz, Sercan Basit, Hasan Sadikoglu, Ozkan Gokcekaya, Takayoshi Nakano, Hakan Yilmazer: Effect of Production Parameters on Additively Manufactured Hastelloy-X Alloy by Selective Laser Melting, in Digitalization in Additive Manufacturing(Edited by Numan M. Durakbasa, Kerim Cetinkaya, Pinar Demircioglu, Ismail Bogrekci), 15 July (2025), pp. 195-204.

eBook ISBN

978-3-031-84873-5

Published: 14 July 2025Series ISSN

2730-9576

Series E-ISSN

2730-9584書籍はこちら

Abstract

Additive Manufacturing (AM), also known as 3D printing, enabled the fabrication of products with complex geometries, layer by layer. It was preferred in various sectors such as aerospace, biomedical, and automotive industries. The formation of different phases in superalloys affected their machinability and contributed to cracking in aerospace applications. Consequently, there has been significant attention on fabricating superalloys with enhanced mechanical and corrosion resistance at high temperatures, especially for parts used in the combustion chambers of turbine engines. Furthermore, microstructural control and preferred orientation (texture) were used in material development to improve performance. In this study, the production parameters of the Selective Laser Melting (SLM) technique for AM were investigated on Hastelloy X superalloys. The study aimed to optimize production parameters by examining the effects of variables such as laser scanning speed (V) on the microstructure and mechanical properties of the material. The microstructures of the produced samples were analyzed using optical microscopy. Hardness measurements were conducted to assess the mechanical properties, while porosity and density, in relation to microstructure, were also examined.

-

2025.7.11

【解説】山陽特殊製鋼技報第32巻(2025年6月発行)に中野先生のAMによる金属材料の高機能化に関する寄敲が掲載されています。

中野貴由:

積層造形(Additive Manufacturing)による 金属材料の高機能化、

山陽特殊製鋼技法 特集:部品製造プロセスの革新に寄与する材料技術、 (2025)、Vol.32 No.1、pp.3~24.

https://www.sanyo-steel.co.jp/technology/images/pdf/32/32_03.pdf -

2025.7.2

【論文】バイオフィルムに関する研究が、Transactions of the IMF (YTIM)にOA論文として掲載されました。

Hideyuki Kanematsu*, Shochiku Kure, Risa Kawai, Hidekazu Miura, Takayoshi Nakano:

Antibiofilm Potential of Graphene-Dispersed Alkoxysilane Coatings:

A Materials Science Perspective, Transactions of the IMF (YTIM),

The International Journal of Surface Engineering and Coatings, (2025).

DOI: https://doi.org/10.1080/00202967.2025.2520667

論文はこちら

PDFはこちら

Abstract

This study investigates the antibiofilm properties of alkoxysilane-based coatings incorporating dispersed multilayer graphene powder. Graphene, synthesised via a proprietary method, was incorporated into a resin matrix at various concentrations (0.1%, 0.5%, and 1.0% by weight) and applied to glass substrates. Raman spectroscopy confirmed the presence of defect-rich, multilayer graphene, which is known to enhance antimicrobial surface properties. Biofilm formation by Staphylococcus epidermidis was evaluated using ISO 4768-standardised crystal violet staining. Results indicated that biofilm development was effectively suppressed at concentrations up to 0.5%, whereas an unexpected increase was observed at 1.0%, possibly due to graphene aggregation and reduced surface exposure. The findings suggest that both graphene concentration and dispersion quality critically influence antibiofilm efficacy. The study highlights the dual role of graphene, both as a physical and chemical antibacterial agent, and its potential application in medical, industrial, and hygienic materials. Further investigation is warranted to optimise dispersion and explore microbial-material interactions in real-world conditions.

Keywords

Graphene-dispersed coatings; alkosysilane resin; biofilm suppression; crystal violet assay; Raman spectroscopy -

2025.7.1

2025年7月1日【解説・論文】中野先生が特集したスマートプロセス学会誌「AM技術の進展と応用(Ⅰ)」が発行され、中野研関係の解説と論文が掲載されました。

中野先生が特集したスマートプロセス学会誌「AM技術の進展と応用(Ⅰ)」が発行され、中野研関係の解説と論文が掲載されました。

Vol. 14[No. 4]、2025(令和7年7月)、AM技術の進展と応用(Ⅰ)、スマートプロセス学会誌

【解説】

★中野貴由、桐原聡秀:巻頭「AM技術の進展と応用(Ⅰ)」、 スマートプロセス学会誌、14[4], (2025), pp.123. ★安田弘行、趙研、竹山雅夫、中野貴由:航空機エンジン用TiAlタービンブレードのAM、 スマートプロセス学会誌、14[4], (2025), pp.175-180.

★森浩亮、金孝鎮、中野貴由、山下弘巳:AM 触媒反応管開発の最前線、 スマートプロセス学会誌、14[4], (2025), pp.181-186.

【研究論文】

★熊谷祥希、髙橋茉莉、小柳禎彦、小笹良輔、中野貴由:レーザ粉末床溶融結合法の造形過程におけるFe基合金の変形挙動に及ぼすマルテンサイト変態の影響、 スマートプロセス学会誌、14[4], (2025), pp.192-197.